How does a LED Strobe Light Achieve Superior Waterproof Performance?

How does a LED Strobe Light Achieve Superior Waterproof Performance?

Blog Article

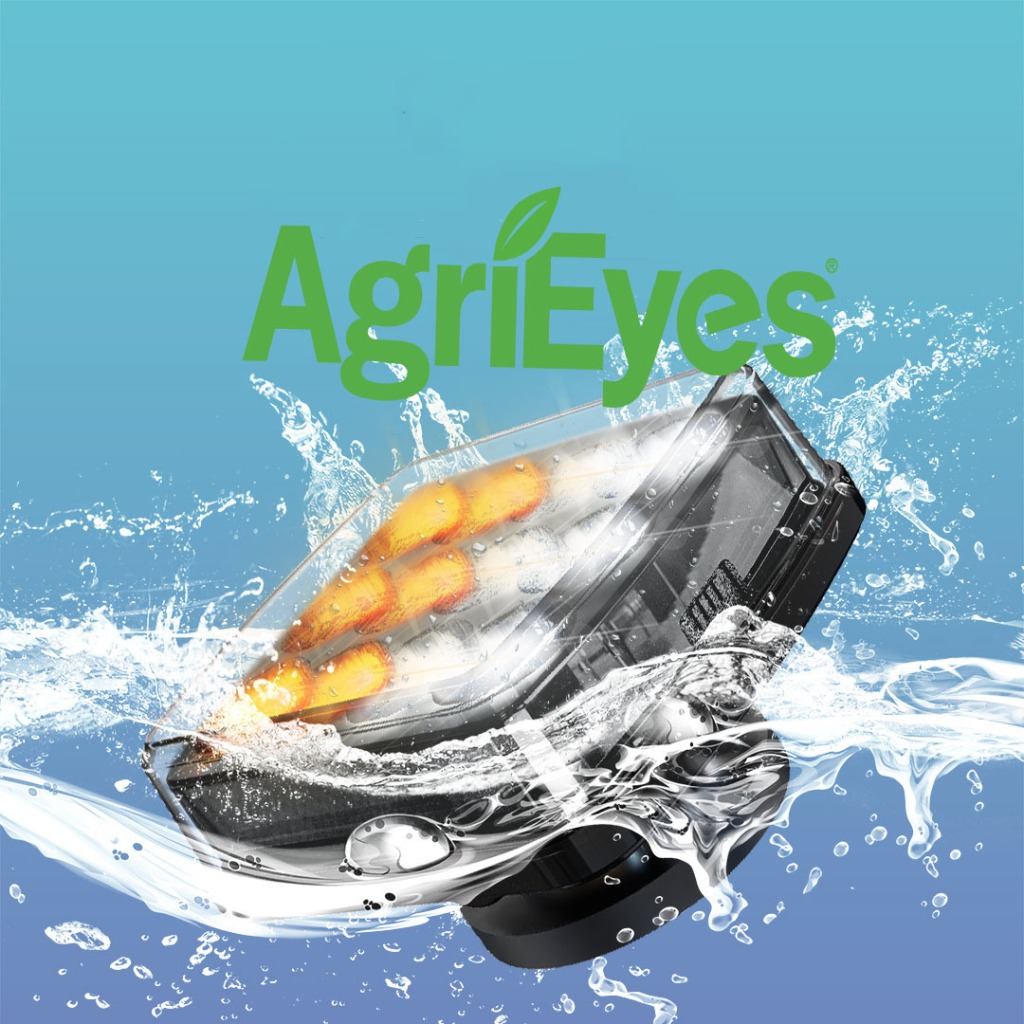

In today’s world, strobe lights are essential safety equipment used in a range of applications, including traffic control, industrial safety, and emergency rescue operations. In order to be effective during bad weather, strobe light bar need to be sturdy and trustworthy. As a result, these lights’ exceptional waterproof performance plays a critical role in determining how long they will last and function. Potting and ultrasonic welding methods have allowed strobe lights to work much better in underwater environments, ensuring their consistent operation.

Using potting technique, liquid glue is injected into the gap between the housing and the circuit board. Spotting successfully seals off any spaces between the circuit board and the housing during the LED strobe light production process, forming a strong barrier against moisture and dust. By employing this method, the mechanical strength and reliability of the circuit board are enhanced.

Potting technology’s outstanding filling ability and sealing effect are its main advantages. Every possible crevice is completely filled by carefully regulating the resin’s flow and curing process, creating an all-encompassing protective covering. As a result, even when submerged or subjected to high-pressure water jets, moisture is prevented from penetrating the circuit board, effectively avoiding short circuits and corrosion caused by water ingress.

High waterproof performance is achieved by completely sealing the circuit board and housing of magnetic strobe light utilizing potting and ultrasonic welding technologies. When combined, these two technologies could greatly improve environmental sustainability and lengthen the life of strobe lights and reduce their maintenance needs. As technology advances, strobe lights’ waterproof performance will continuously improving, and will finally provide more dependable support for public safety.

Ultrasonic welding is unquestionably a significant role in improving the waterproof performance of strobe lamps. It minimizes the chance of water seeping in through joints by achieving seamless connections at the housing’s edges. Furthermore, the welds produced by this technology are exceptionally strong and resistant to distortion or breaking, even in the face of extreme mechanical stress. That’s mean the strobe light bar will live a long lifespan that you could use it without any worries about what happen if it fail. This high-strength, seamless connection greatly improves the strobe light’s overall sealing integrity, ensuring dependable performance in muddy, rainy, and snowy conditions.

Potting and ultrasonic welding technologies combine to provide dual protection for LED strobe light. Ultrasonic welding ensures a perfect seal on the housing, while potting technology fills the circuit board and shields it from outside influences. By combining these technologies, a totally waterproof covering is produced, extending the durability and adaptability of the LED strobe light to different environments.

Strobe lights function particularly well in severe weather and tough locations because to their dual protection system. Strobe light bar is capable of reliable operation and continuous warning functions in every weather condition, including severe rain, thick snow, and muddy roads. This increases the equipment’s dependability and offers users more value by drastically lowering the need for maintenance and replacements.

Because these strobe lights have a high correlation between their longevity and functionality and their ability to withstand adverse conditions, they are an ideal warning tool. To achieve high waterproof performance, the circuit board and housing of strobe lights are completely sealed by utilizing potting and ultrasonic welding technologies. When combined, these two technologies improve environmental sustainability and lengthen the life of strobe lights and reduce their maintenance needs as well. As technology advances, strobe lights’ waterproof performance will also increase, providing more dependable support for public safety.